Description

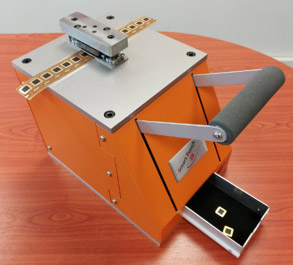

- The SPu20 manual punching unit allows getting a chip, a contact plate or a fingerprint sensor out of a film, one by one. The component can then be manually embedded into a card cavity using the SI20.

- The SPu20 manual punching system is supplied with a die & punch tool designed to fit with the component to punch.

- The die & punch tool can be replaced with another set to support another component design, forinstance a chip (6 or 8 pins) or a contact plate.

- The SPu20 is not needed for IDEX sensors as they can be easily removed manually from the paper-line.

- The SPu20 is made in France.

- Equipment overview for milling, lamination, embedding, personalization.

- Alternative solutions for lamination: 1)Use an OEM laminator supplied by STS. 2)Use your existing laminator, or a laminator from another brand. 3)Outsource lamination to STS

- Alternative solutions for card milling: 1)If the sensor is in the ISO position when the card is turned 180°, then an existing milling machine can be used (by turning all cards by 180°). 2)Use an OEM manual milling system supplied by STS, able to mill in various positions. 3) If a MPR5000 or MPR5800* with a milling module is available, then STS can adapt it to be able milling in any position .

- Embedding with the SI20 semi-automatic presser heads system: The SI20 allows testing/tuning a process by manually embedding sensors, chips or contact plates on test cards – before producing cards in volume with the SI700.

- SPu20 Manual punching system: Use the Manual Punching system Smart Punch 20 (SPu20) to get a sensor from the film .

- SI700 automatic card embedding system:A versatile desktop automatic card embedding system for contact cards, dual interface cards and biometric cards.

SI700 options

Various options can be offered for the SI700, including:

o Additional toolkit(s) to support additonal component(s) like chips, contact plates, other sensors

o A vision control station before the embedding station – to check the milling cavity

o A vision inspection station after the embedding station – to check the component placement

o An electrical contactless test station after the presser heads station – to test the card through the contactless protocol (ATS)

Reviews

There are no reviews yet.