Description

SI20 product objective and positioning

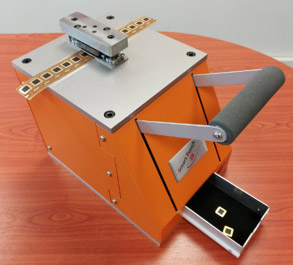

The SI20 is a semi-automatic presser heads system allowing pressing 1 or several times a chip module, an ISO plate or a fingerprint sensor on a card. The 2 presser heads allow reproducing a standard embedding process, typically with the first head heating the component, and the second head cooling it. Each embedding parameters can be controlled including the pressing temperature, the pressing time, and pressure force.

This simple and affordable system allows performing various embedding tests on cards in a view tuning a process before implementing it into a bigger system like the SI700. For some particular projects where:

– specific or new components need to be embedded on cards, like a particular fingerprint sensor,

– particular card material needs to be used, like metal cards or others,

– a particular/new adhesive and/or conductive glue need to be used,

– a particular embedding process,

– a pilot, experiment or tests need to be conducted using a small quantity of cards,

then the SI20 is the perfect system to exercise these new elements and related embedding parameters on a small quantity of cards, before launching a production.

The SI20 is mainly used for engineering purposes. It avoids using a production system to exercise a new technology or new card products. It has been designed to bring a maximum of flexibility:

– All embedding process parameters are adjustable: temperature, pressure force, pressure time.

– It can embed chip modules, contact plates and fingerprint sensors in any position on the card, except 1mm from the right/left edge of the card, and 2mm from the top/bottom of the card.

– Presser heads can be easily changed to accommodate the component design, depending on the chip module / contact plate / fingerprint sensor used.

– It supports various card materials: PC, PVC, ABS, PET, composite, metal.

– It can be used to manually produce small volumes of cards, including:

o Contact cards, with a single chip or with multiple chips

o Dual interface cards

o Biometric cards

SI 20 general specification

| SI20 Specification | |

|---|---|

| System Functionality | Press a chip module, a contact plate, a biometric sensor or eventually a smart object in any position on the card surface except 1mm from the right and left edge of the card, and 2mm from the top and bottom of the card. |

| Preliminary conditions | – A cavity should be milled on the card – The chip/contact plate/sensor film should be laminated with an adhesive glue |

| Embedding Placement | Placement is done manually |

| Connecting technologies to the card inlay |

2 supported technologies allow connecting the chip, contact plate or sensor to the contact pads of the card inlay: – ACF glue (Anisotropic adhesive conductive glue) – Edgelink® from Linxens |

| Presser heads temperature, pressure force, pressure time |

– From ambiant to 300°C – Pressure force up to 6 bars – Pressure time up to 20 sec |

| Card Types Supported | ISO/IEC 7810 ID-1 Size; 30 mil (±10%) |

| Card Materials Supported | Polycarbonate, composite, PVC, ABS, metal |

| System dimensions | H 336 mm x W 396 mm x L 450 mm |

| Power supply / Compressed air | 120V / 240V, 50 or 60 Hz / Compressed air: 6 bars, 8 liters/minute |

Reviews

There are no reviews yet.