Description

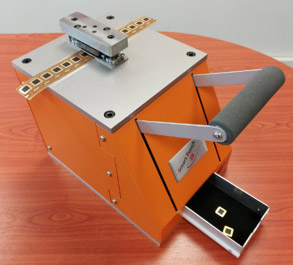

Designed to target multiple markets including Financial, ID, Access Control, Telecom and others, the SI700 is a midrange system able to embed chips, contact plates or fingerprint sensors into cards.

Chip or sensor embedding in any position..

Configuring the system for chips or for sensors only takes few minutes and just requires changing a toolkit. The system can embed fingerprint sensors in any position on pre-milled cards. This capability solves the manufacturing issue resulting from the lack of standards for biometric cards on the sensor position.

..and in any direction

Depending on the card design, the SI700 can adapt the fingerprint sensor orientation on the card during embedding. Once the sensor is punched and removed from the sensor film, the embedding station can turn the sensor orientation to 90°, 180°, 270° when needed so that the sensor contact pads can properly connect with the right contacts on the card inlay.

Smart Inserter 700 Specifications

| System Functionality | Implement either a chip, contact plate or biometric sensor on all the card surface except 1mm from the right and left edge of the card, and 2mm from the top and bottom of the card |

| Preliminary conditions | – A cavity should be milled on the card, depending on the chip or sensor specification – The chip, contact plate or sensor film should be laminated with glue |

| Connecting technologies to the card inlay | 2 supported technologies allow connecting the chip, contact plate or sensor to the contact pads of the card inlay: Edgelink from Linxens, or ACF glue (Anisotropic adhesive conductive glue) |

| Rated Speed | Up to 700 cards/hour. Exact throughput dependents on the exact time needed to press the chip, contact plate or sensor using the hot presser head stations |

| Chip or sensor cutting accuracy | ± 30 µm. Cutting is performed using a tooling designed as per the chip/plate/sensor specification |

| Embedding Placement | ± 50 µm. Embedding is performed using a pick&place system |

| Chip or sensor film | – Standard S35, 35 mm (1.38 in.) – Pitch: 14.25, 9.5 mm (0.37 in.) |

| Presser heads temperature, pressure, time | – From ambiant to 250°C – Pressure force up to 6 bars – Pressure time up to 20 sec |

| Card Types Supported | ISO/IEC 7810 ID-1 Size; 30 mil (±10%) |

| Card Materials Supported | Polycarbonate, composite, PVC, ABS. The card material may influence the choice of the glue, and parameters used on the hot presser heads (temperature, pressure force, pressure time) |

| System dimensions | H 280 mm x W 340 mm x L 1500 mm without the tape storing the chip/contact plate/sensor film |

| Module weight | 60 kg without the tape storing the chip, contact plate or sensor film |

| Power supply / Compressed air supply | 120V / 240V, 50 or 60 Hz / Compressed air: 6 bars, 8 liters/minute |

Reviews

There are no reviews yet.